Do you need technically clean seals?

When it comes to cleanliness, we go deeper!

At OVE Plasmatec GmbH, we take a deep look at cleanliness. We clean seals using specially developed methods.

Since 2000, “technical cleanliness” has been an important indicator of quality in the automotive and OEM industries. And other industries also require consistently clean components and component groups. This is especially true for elastomer seals. When seals are delivered, they are often dirty or stuck together, which makes assembly more difficult and can impair their functionality.

We reliably remove production residue from elastomer surfaces using wet cleaning.

Wet Cleaning

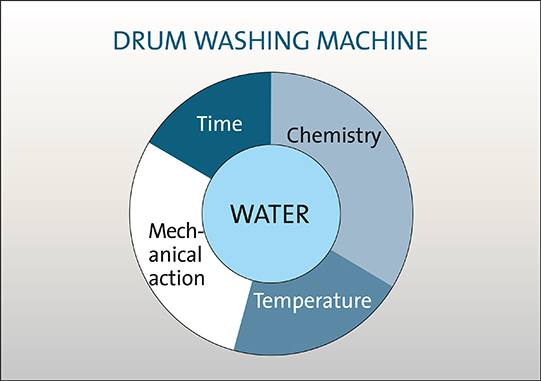

We conduct a thorough wet cleaning using a drum washing process to remove production residue such as grease, oils, etc. Subsequently, the clean elastomer parts are gently dried.

The following illustration shows the parameters used in the washing process.

Illustration: “Circle of Sinner” (cleaning process model developed by the German chemist Herbert Sinner)

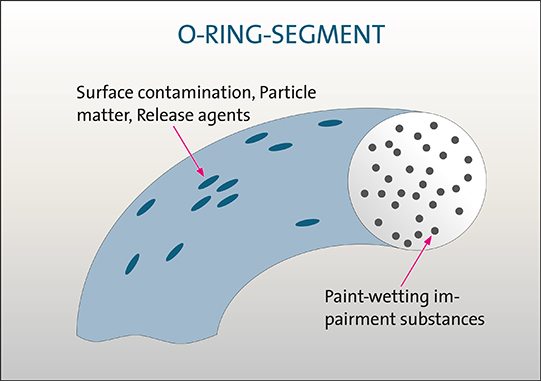

Illustration: O-ring segment BEFORE cleaning

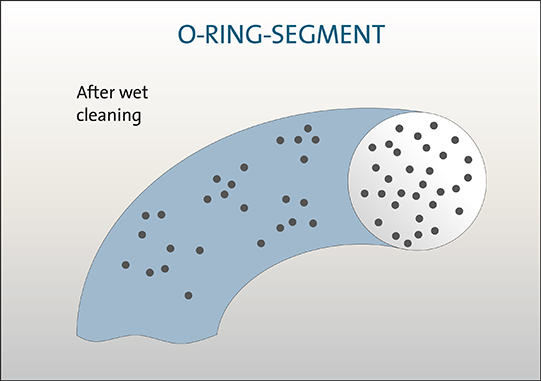

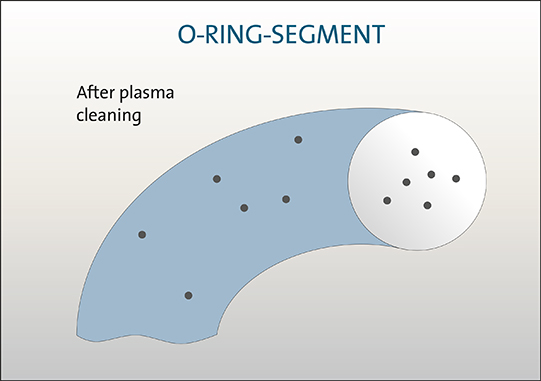

Illustration: O-ring segment AFTER cleaning

After cleaning and drying, the elastomer parts’ surfaces are residue-free.

Plasma cleaning yields PWIS-free surfaces (meeting 'LABS' standards)

For an even more immaculate result, we turn to plasma cleaning. In the mid-1990s, OVE became the first company to apply this technology to elastomers. During plasma cleaning, elastomer components undergo an additional deep cleaning. The result is a true deep clean with no lingering residues or particle contaminations which could affect functioning.

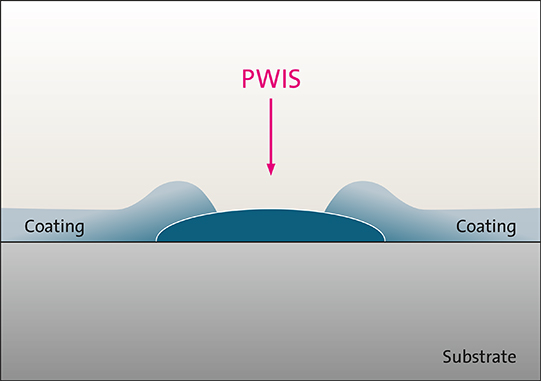

PWIS stands for paint-wetting impairment substances (also known by their German abbreviation LABS). These substances prevent uniform wetting of the surface which is being coated, causing funnel-shaped defects and craters in the coating. Ever since solvent-free coatings (more accurately: low-solvent coatings) were introduced in the automotive industry, there has been a need for production materials, machinery and tools that comply with fixed standards for PWIS levels (LABS conformity). In the pre-treatment of surfaces to which adhesives will be applied, it is likewise advisable to avoid surface defects, as they reduce adhesion strength. Since it is not known which substances lead to these defects, the materials, components and component groups used are tested for conformity.

While intensive cleaning is able to thoroughly remove production-related substances (release agents, coolants, etc.) that have adhered to the surfaces of metals and many plastics, surface cleaning is not sufficient in the case of elastomers. For materials with certain compositions, it is not enough to remove residual production-related substances from the surface; in such cases, the main challenge is extracting diffused (unbound) mixture components, such as plasticisers.

After intensive wet cleaning with specially developed cleaners, parts are then deep-cleaned in low-pressure oxygen plasma with oxidation.

Illustration: O-ring segment AFTER cleaning

How plasma cleaning works

The low-pressure plasma process involves adding energy to oxygen gas under vacuum conditions, thus exciting the gas (microblasting). This causes oxygen radicals (O) and ozone (O3) to form. Reactive residues (oils, grease, etc.) are oxidised and evacuated as a gas (CO, CO2, H2O) or in particulate form.

The plasma principle is explained here in detail: » download (PDF 105 KB)

Testing for conformity with PWIS standards (LABS conformity)

The most widely used test standard is Volkswagen’s PV 3.10.7. The components to be tested are placed on a glass plate and wetted with a solvent mixture. The solvent evaporates, then the coating is applied to the test plate; if craters (displacements of the coating) occur, the standard is not met. Other test specifications and standards use similar procedures.

Illustration: surface malfunction

Beyond the VW standard, OVE also tests for LABS conformity according to the following standards:

• FESTO FN 942010-2

• DÜRR QZ 24

• VDMA 24364-A1/B1-L*

Depending on the conditions in which they are stored and used, materials with high levels of PWIS-containing substances may become recontaminated via diffusion.

*OVE was actively involved in the development of the VDMA guide » download (PDF 899 KB), bringing its many years of practical experience to the table.

Why OVE is the right partner for you

OVE has developed a process for cleaning elastomers which ensures the strictest possible compliance with PWIS standards. This process has proven itself over more than 30 years across a diverse array of industries, and is consistently re-evaluated to ensure it keeps pace with technological change. The OVE cleaning process achieves outstanding results by relying on tried and tested parameters like time, temperature and machinery – and the interplay between them.